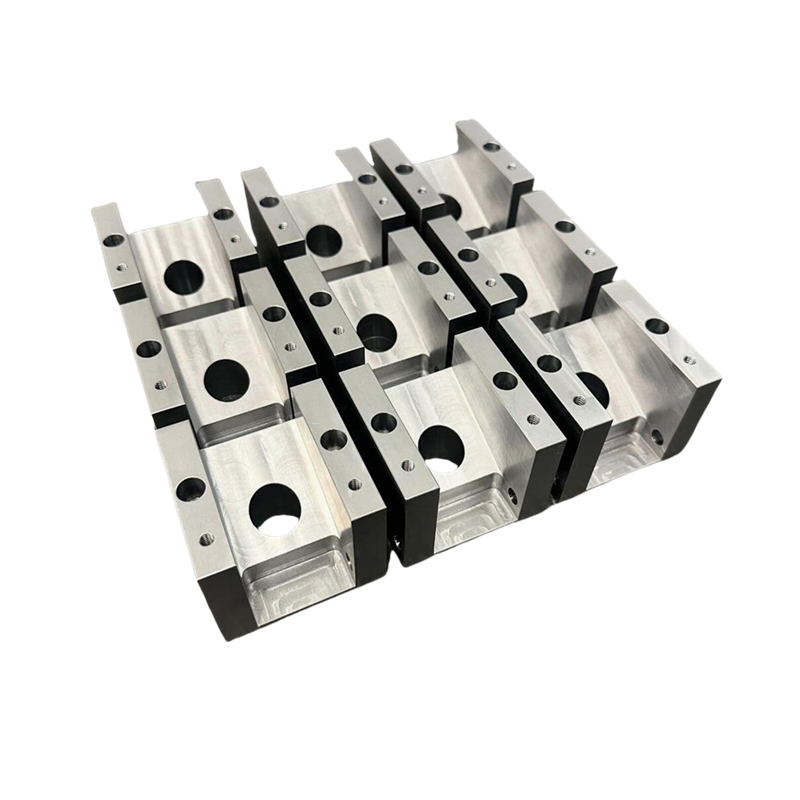

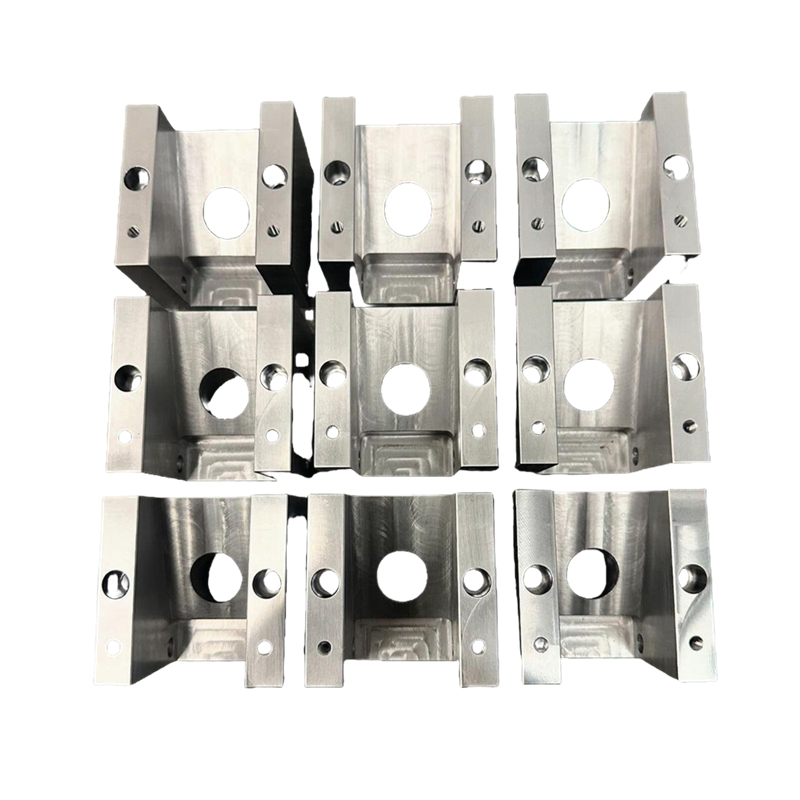

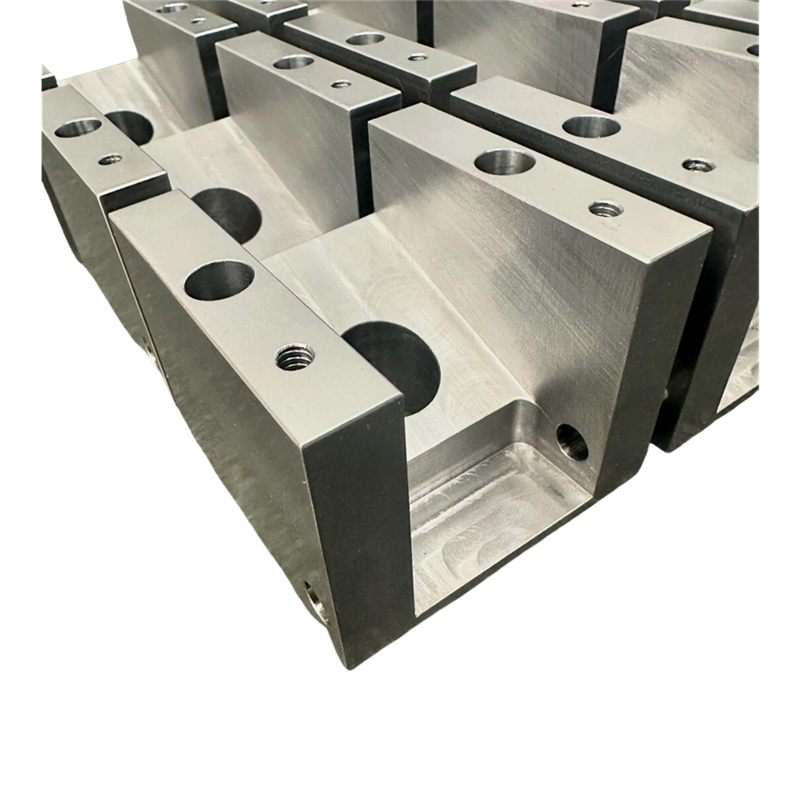

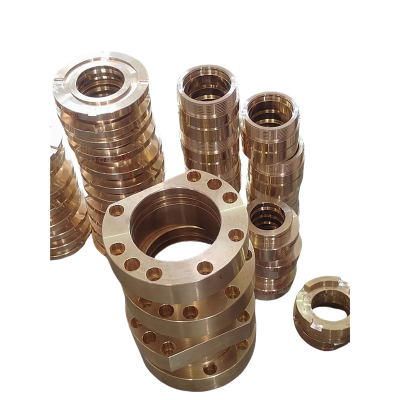

China workshop custom made precision 304 stainless steel components

ACE Precision Manufacturing Co., Ltd, can process machining which is applicable to a wide range of products and cover several industries. The following are some common application areas and product types:

1. Machine manufacturing

- Machine parts: e.g. spindles, guideways, screws, etc.

- Transmission parts: e.g. gears, shafts, couplings, etc.

- Hydraulic components: such as hydraulic cylinders, valve bodies, pump bodies, etc.

2. Automobile industry

- Engine parts: such as crankshafts, camshafts, pistons, etc.

- Chassis parts: such as suspension arms, steering knuckles, brake discs, etc. Drive train parts: such as gears, gears, etc.

- Transmission system parts: such as gears, clutches, drive shafts, etc.

3. Aerospace

- Engine parts: e.g. turbine blades, compressor disk, combustion chamber, etc.

- Airframe structural parts: such as wing girders, fuselage frames, landing gears, etc.

- Avionics parts: such as sensor brackets, connectors, housings, etc.

4. Electronics industry

- Heat sinks: for CPU, GPU and other electronic components of the heat dissipation.

- Shell: such as cell phones, computers, servers and other equipment shell.

- Connectors: such as USB ports, HDMI ports, etc.

5. medical equipment

- Surgical instruments: such as scalpels, forceps, scissors, etc.

- Implants: such as artificial joints, dental implants, etc.

- Testing equipment parts: such as the internal parts of CT machine, MRI machine.

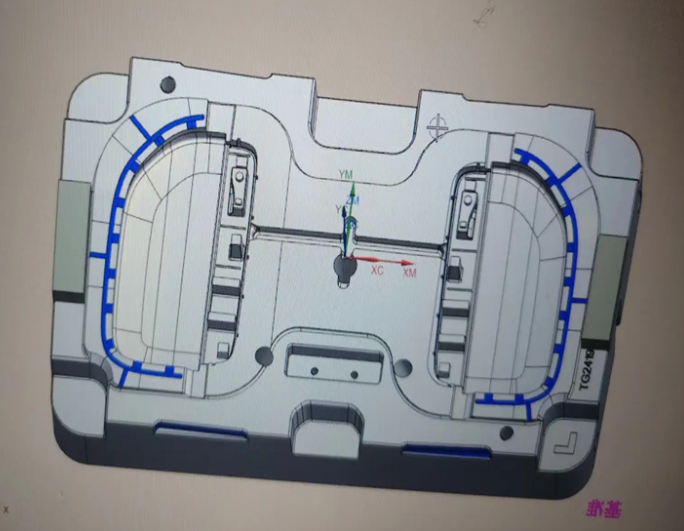

6. Mold manufacturing

- Plastic injection molds: used for molding of plastic products.

- Stamping mold: used for metal sheet molding.

- Die-casting molds: for metal die-casting molding.

7. Energy industry

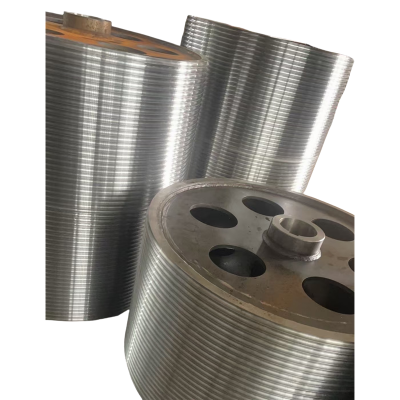

- Turbine parts: such as gas turbine blades, steam turbine blades.

- Pump and valve parts: such as centrifugal pumps, valves, pipeline connectors, etc.

- Nuclear energy equipment parts: such as reactor internal parts, cooling system parts.

8. Shipbuilding

- Engine parts: such as diesel engine crankshaft, piston, etc.

- Propulsion system parts: such as propellers, shaft systems, etc..

- Hull structural parts: e.g. hull frames, deck supports, etc.

9. Construction

- Steel structure parts: such as steel beams, steel columns, connectors, etc.

- Construction machinery parts: such as excavator, crane, concrete pump truck parts.

10. Household appliances

- Compressor parts: such as refrigerator, air conditioner compressor parts.

- Motor parts: such as washing machines, vacuum cleaner motor parts.

- Shell and bracket: such as TV, stereo shell and bracket.

11. Optical instruments

- Lens: Used in cameras, microscopes, telescopes, etc.

- Prisms: used for optical path adjustment in optical instruments.

- Mirror tube: used to fix and protect optical elements.

12. tools and fixtures

- Tools: such as milling cutters, drills, turning tools.

- Gauges: such as calipers, micrometers, gauges, etc..

- Clamps: such as vise, chuck, positioning jigs, etc.

13. Customized parts

- Prototype parts: for product development and testing.

- Special shaped parts: such as complex curved parts, shaped parts, etc.

- Small-lot production parts: for customization needs.

14. Other industries

- Food machinery parts: such as mixers, cutters, conveyor belt parts, etc.

- Textile machinery parts: such as spinning machine, loom parts.

- Packaging machinery parts: e.g. parts for sealing machines, labeling machines.

The machining process is applicable to almost all metallic and non-metallic parts that require high precision, complex shapes and high-quality surfaces. Whether it's high volume production or small customized batches, machining can meet diverse needs.

From models to products, we are your reliable one-stop precision custom parts manufacturer:

Here are some Surface treatment processes we can do to improve the appearance, corrosion resistance, wear resistance, hardness and other properties of the part. The following are some common surface treatment processes:

1. Electroplating

- Zinc plating: to improve corrosion resistance, commonly used in steel parts.

- Chrome plating: to improve hardness, wear resistance and corrosion resistance, commonly used in decorative and functional parts.

- Nickel plating: improve corrosion resistance and wear resistance, commonly used in electronic components and decorative parts.

- Gold/silver plating: improve conductivity and decorative, commonly used in electronic components and jewelry.

2. Chemical plating

- Electroless nickel plating: uniform plating, improve corrosion resistance and wear resistance, suitable for complex shape parts.

- Chemical copper plating: improve conductivity, commonly used in electronic industry.

3. Anodizing

- Aluminum anodizing: improves corrosion resistance, wear resistance and decorative properties of aluminum and its alloys, commonly used in aerospace and consumer electronics.

- Hard anodizing: further improves hardness and wear resistance, suitable for high abrasion environments.

4. Phosphating

- Zinc phosphating: improves corrosion resistance and lubricity, commonly used for automotive parts.

- Manganese phosphating: improves wear resistance and lubricity, commonly used on gears and bearings.

5. Passivation

- Stainless steel passivation: improves corrosion resistance and removes free iron from the surface, commonly used in the medical device and food industries.

6. Coating

- Powder Coating: Provides a uniform coating, improves corrosion resistance and decorative properties, suitable for metal parts.

- Spray Painting: Provides a protective and decorative coating for a wide range of materials.

7. Thermal spraying

- Flame Spraying: Improves abrasion and corrosion resistance and is suitable for large parts.

- Plasma spraying: Provides high quality coatings for demanding environments.

- Arc Spraying: Improves abrasion and corrosion resistance and is suitable for large structural parts.

8. Heat treatment

- Hardening: Increase hardness and strength, applicable to steel parts.

- Tempering: Reduces brittleness and improves toughness, applicable to hardened steel parts.

- Carburizing: improves surface hardness and wear resistance, applicable to mild steel parts.

- Nitriding: improves surface hardness and corrosion resistance, applicable to alloy steel parts.

9. Chemical treatment

- Blackening: to improve corrosion resistance and decorative properties, commonly used in steel parts.

- Acid washing: remove oxidized skin and rust, improve surface quality, applicable to stainless steel and carbon steel.

10. Mechanical treatment

- Shot peening: improve surface hardness and fatigue strength, applicable to metal parts.

- Polishing: Improve surface finish and decorative properties, applicable to a variety of materials.

- Grinding: Improve dimensional accuracy and surface finish, applicable to high precision parts.

11. laser processing

- Laser hardening: improves surface hardness and wear resistance, suitable for localized treatments.

- Laser cladding: improve surface wear resistance and corrosion resistance, suitable for repair and strengthening.

12. Vacuum Coating

- PVD (Physical Vapor Deposition): Improve surface hardness, wear resistance and decorative properties, suitable for tools and molds.

- CVD (Chemical Vapor Deposition): Improve surface hardness and wear resistance, suitable for demanding environments.

13. Other treatments

- Electrophoretic coating: Provides a uniform coating, improves corrosion resistance and decorative properties, suitable for automotive parts.

Pack and Delivery: